Learn about all the different types of packaging tapes and their benefits.

You might not think about it much, but packaging tapes are super important in business, especially if you send out lots of products to your customers. Have you ever wondered which type of packaging tape best fits your needs?

Well, you're in luck!

In this post, we'll dive into all the different types of packaging tapes and their benefits. Plus, you'll discover the fantastic perks of using packaging tape and get some tips on how to pick the right one for your business.

Let's get started!

What are Packaging Tapes?

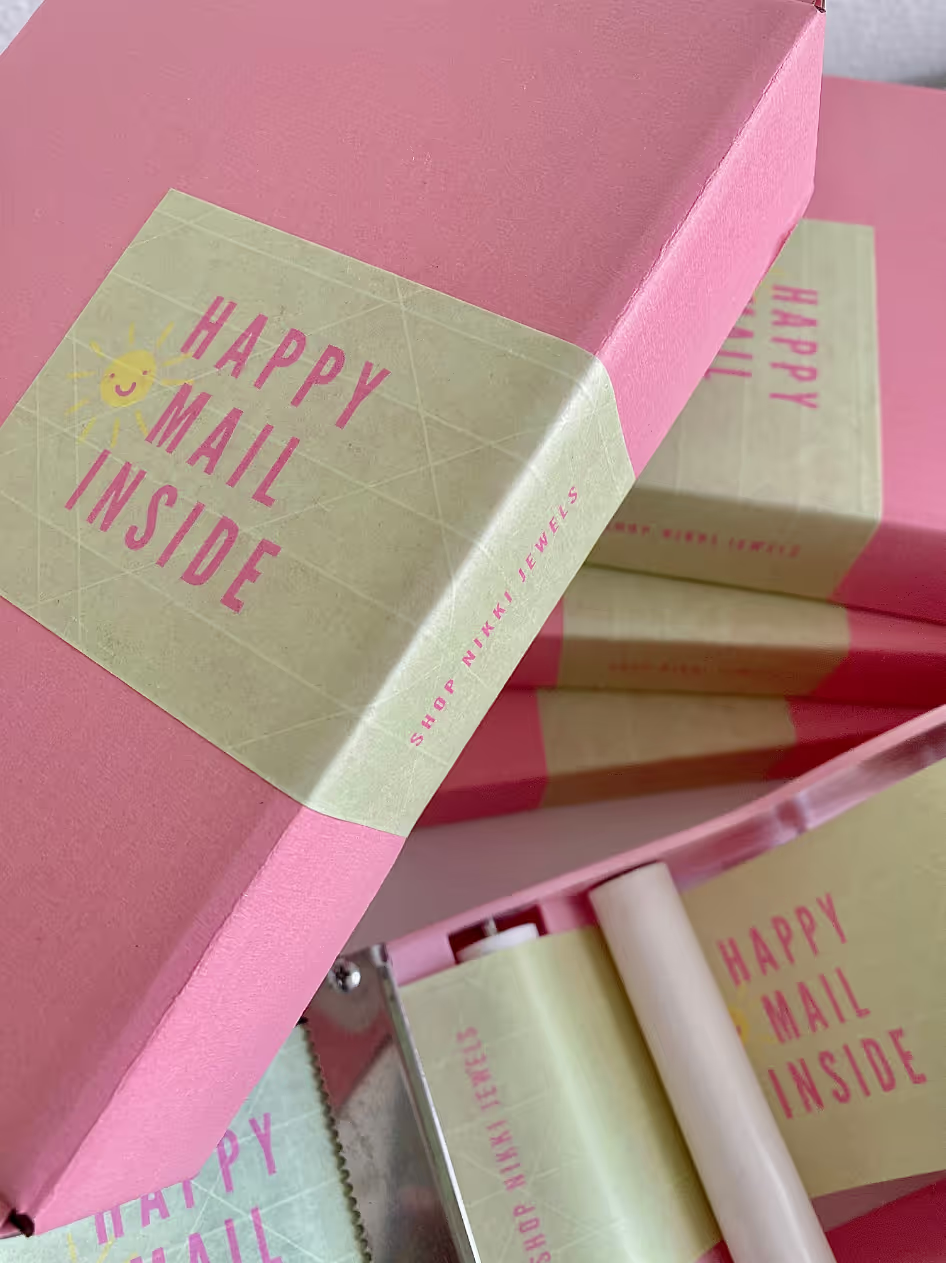

Custom Jewelry Tape by Nikki Jewels

Packaging tapes are adhesive tapes you use to close up boxes and other packaging materials before sending them to customers or storing them in your facility.

There are a few types — Acrylic, Hot Melt, Natural Rubber, and Water-Activated. Some stick as soon as you press them down while some need a bit of water to get going. They're usually made from plastic, PVC, or even paper. They're designed to be really strong and sticky so your packages stay shut during transport.

These packaging tapes are handy for businesses that need an affordable way of securing and adding branding to their packaging.

Types of Packaging Tapes

Business owners like yourself have to know that there are different types of packaging tapes you could use to seal boxes before shipping. Here are some of the most popular options.

Acrylic Tape

Acrylic packing tape has a plastic strip with special glue on one side. If a package gets sealed with clear tape, there's a good chance you're looking at acrylic tape.

It's the go-to choice for sealing boxes because it's easy to use and widely available. Unlike some other tapes, acrylic tape stays strong over time. It's reliable because it doesn't get damaged by sunlight or air.

Acrylic tapes stick well even on dusty or dirty surfaces which is ideal for busy places like factories. However, it might create a strong bond that makes it hard to remove especially if you're using it on thin plastic.

Hot Melt Tape

Hot melt tape is impressive because it sticks fast and it's incredibly durable. It has three layers: a thin film, a coating that helps it unwind smoothly, and a strong adhesive layer.

This tape material is typically applied using machines. Hot melt tape works well in temperatures between 45 and 120 degrees Fahrenheit and is easy to handle. It's used for shipping, storing, and sealing boxes.

Overall, hot melt tape is stronger than acrylic tape, especially for big or heavy boxes.

Natural Rubber Tape

Natural rubber tape comes from the sap of rubber trees. It sticks really well, making it great for sealing boxes tightly so they stay shut while being moved.

This tape works on many surfaces like cardboard, paper, and plastic and keeps its stickiness even when it gets hot or cold.

Water-Activated Tape

Water-activated packaging tape—also known as gummed paper tape—offers a strong and secure alternative for sealing your boxes. Made from reinforced paper and activated with water, this tape forms a powerful bond with cardboard which makes it ideal for heavy-duty packages.

But its benefits go beyond strength. Water-activated tape creates a strong seal, acting as a deterrent against theft. Plus, it performs well in extreme temperatures, so you can be confident your packages arrive safely regardless of the weather.

Worried about the environment? Water-activated tape is biodegradable and compostable, making it a sustainable choice.

And for businesses looking to leave a lasting impression, water-activated tape can be customized with your logo or design, transforming it into a branding tool on every box you ship.

Finally, the clean look of water-activated tape contributes to a more positive unpacking experience for your customers.

Benefits

Why should you use packaging tape? It's not just about sealing your packages. Custom packaging tapes have other benefits too.

Branding and Promotion

Packaging tape isn't just for sealing boxes. It's a great way to show off your brand! By adding your logo, slogan, or other cool designs to the tape, you can make your packages stand out.

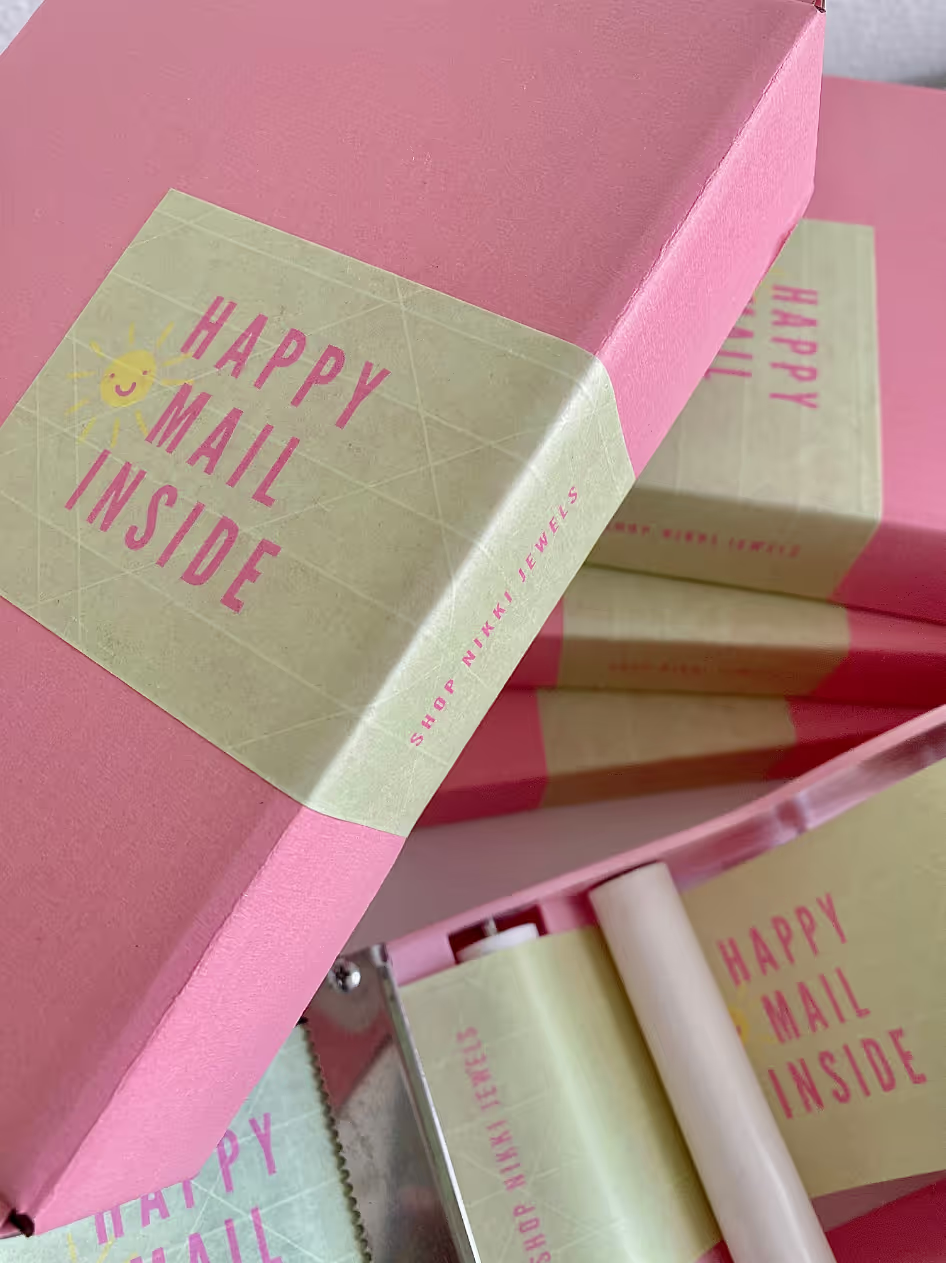

Packaging Tape by Remi and Oliver

Packaging tape works like a mini billboard that goes wherever you send your packages. It catches the eyes of everyone from warehouse staff to the final customer. It's a simple yet clever way to spread the word about your business during shipping.

Plus, it makes receiving and opening boxes more exciting for your customers. Packaging tape leaves a strong, positive impression of your brand. They're a budget-friendly and creative way to make your business shine and stick in people's minds.

Security

Packaging tape is essential for keeping shipping boxes safe during transport. It shows if someone has tried to open the package because the tape can't be removed without leaving marks. This helps prevent tampering and theft.

Plus, using tape keeps the package sealed tight so nothing falls out. You can even customize your packaging tape design to deter people from ripping it off since they're harder to replace.

Choosing the Right Tape

What type of packaging tape will work best for your business? Below are some of the factors you have to consider.

Packaging Weight and Size

There are a few things you have to consider when picking the right packaging tape.

Figure out how heavy your packages are so you can choose a tape that's strong enough to hold during transport. For lighter packages, regular tape is fine. But for heavier ones, you might need stronger tape.

Surface Compatibility

It's also important to think about surface compatibility. You want to use tape that would stick to your packaging's surface. If you're using cardboard boxes, for example, then you'll want to use acrylic or water-activated packaging tapes.

Environment/Weather Conditions

Also, consider the weather conditions your packages will face while being shipped. Some tapes perform better under extreme temperatures.

Look for packaging tapes that can handle moisture—like water-activated or waterproof ones—for rainy days to keep packages sealed tight.

For extreme heat or cold, find tapes that won't lose their stickiness. If sustainability is a huge priority for your business, use tapes made from recycled materials or those that can break down naturally. This way, you can make sure your packages are well-protected during shipping—no matter the weather—while also being kind to the planet.

How to Apply Packaging Tapes

Here's how you properly apply packaging tapes to get the best results.

Surface Preparation

To ensure your packaging tape sticks properly and lasts longer, clean the surface with a clean cloth to remove any dust or dirt. Make sure it's completely dry. Remember to smooth out any bumps or creases.

Dispensing Techniques

Pull out around 6 to 8 inches of tape and stick it onto the package. Make sure it's tight. Roll the tape across with one hand while pressing down firmly to make it stick. Finally, cut the tape using the dispenser's blade and repeat as needed to fully seal the package.

Using a tape dispenser will make short work of sealing packages.

Overlapping and Sealing

Apply a strip of tape along your package's opening so that it stays secure. You can then overlap each strip by about 0.5 to 1 in. This method strengthens the seal and keeps everything tight, especially at the edges and corners which can be tricky spots.

Packaging Tape Samples

Here are a few packaging tape design examples to help you create ones you can use for your business.

Packaging Tape Design by Pop! Shop Jewelry

Illustrated Packaging Tape by Munespice

Bakery Packaging Tape by Emily Retamozo

Custom Packaging Tape by Whattacharmer

Conclusion

So, you've unwrapped the secrets of packaging tape! Now you can choose the perfect tape to secure your packages and elevate your brand.

You can transform plain, brown shipping boxes into mini billboards. Think about it: Every package you ship becomes a mobile advertisement, subtly promoting your brand to everyone who handles it.

It's a cost-effective way to boost brand awareness and leave a lasting positive impression.

But that's not all.

The right packaging tape goes beyond aesthetics. It acts as a security measure, with tamper-evident seals that deter theft and ensure your products arrive exactly as they left.

With so many benefits and varieties, the perfect packaging tape is waiting to take your business to the next level.

If you'd like to learn more about custom packaging tapes, call or chat with one of PackM's customer representatives. You can also email us at sales@packm.com