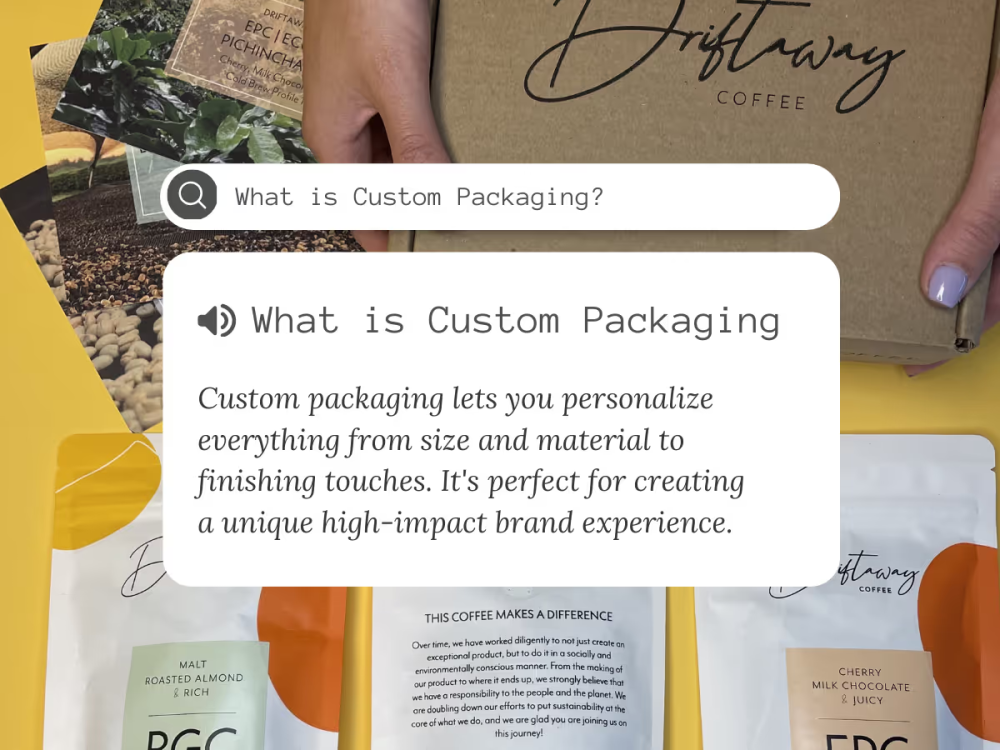

Confused by packaging terminologies? Come learn the most common terms you may encounter.

Creating custom packaging is a must for any business looking to stand out from the crowd.

The world of packaging has its own language, but understanding some basic terms can be a big step forward.

In this post, we'll crack the code on some of the most common terms you'll encounter in the world of custom packaging. We'll break them down in a clear and concise way, empowering you to navigate the ordering process confidently.

Materials

These are some terms you'll likely come across when selecting packaging materials.

Cardstock

Cardstock is a thick, durable paper used for making different kinds of packaging like boxes and inserts. It's stronger than regular paper but not as thick as cardboard.

It's regularly used for packaging because it's sturdy yet easy to design. It comes in various thicknesses and finishes. Companies should choose what cardstock best fits their brand and product needs.

Corrugated Board

A corrugated board—or corrugated cardboard—is a sturdy packaging material with one or more flat linerboards. It's wavy middle layer provides strength and cushioning.

Box manufacturers use corrugated boards to make shipping boxes because of their light but rigid properties. They can handle bumps and drops (within reason) without damaging their content. Corrugated boards are eco-friendly since they're recyclable.

Kraft Paper

A champion of durability, Kraft paper offers a naturally beautiful brown color, making it both tough and aesthetically pleasing.

You can find kraft paper in different everyday packaging like gift wraps, shopping bags, and even envelopes. Businesses love it because it's affordable. It's also kind to the planet because of its recyclability. You can customize this material to add branding elements to your packaging.

Plastic Film

Plastic film is a thin material made from synthetic polymers. It's commonly used to wrap products. The plastic gets melted and shaped into sheets that can be as big or small as needed.

This material is excellent at keeping your items fresh by protecting them from air, water, and light. It's flexible, so it wraps around anything snugly. You can see through it to check what's inside without opening it.

While plastic film offers convenience, responsible disposal is crucial to minimize its environmental footprint.

Design and Printing

Below are terms you'll encounter as you design and print your packaging materials.

CMYK, RGB, PMS

When working with colors for your designs or packaging, you'll come across three main color models: CMYK, RGB, and PMS.

Which should you use when designing and printing custom packaging?

- CMYK — Think of CMYK as the go-to color model for printing. It mixes cyan, magenta, yellow, and key (black) inks to create a bunch of colors. Since it takes colors away from white to make new ones, it's perfect for printing your awesome graphics on boxes or flyers.

- RGB — RGB is the standard color model for screens. It mixes red, green, and blue light to make colors shine on your computer, TV, or phone screen. People rarely use this color model when designing packaging.

- PMS — PMS stands for Pantone Matching System. It's super precise. Use PMS if you've got a specific color in mind for your brand or logo. Its unique code will ensure colors remain consistent throughout all your packaging and marketing materials.

When in doubt, use CMYK.

DPI and Resolution

You'll hear a lot about DPI and resolution as you work on your custom packaging design. But what do these terms mean?

Here's the breakdown.

- DPI — Stands for dots per inch. Think of it like the number of tiny dots that fit into a one-inch line of your image. More dots mean a clearer picture. The higher the DPI, the clearer your design elements will be.

- Resolution — A broad term that refers to how clear an image is. It considers both the DPI and your image's pixel size. When choosing images for your packaging, keep both resolution and DPI in mind. Both ensure packaging designs turn out crisp after printing. Having high-resolution images means you've got more room to adjust size without losing quality.

So, DPI is about how dense the dots are in your print, making it detailed. Resolution ties into the overall quality and clarity of your images.

Bleed

Bleed is the area of the print that goes beyond where your artwork gets cut. It ensures your packaging doesn't end up with unprinted edges after it's cut to size.

When you're designing custom packaging, make sure to extend your design a bit past the trim size. You can use a design template to see where your bleed is supposed to be.

Basically, bleed keeps everything looking neat and complete. Add bleed to your design files to get a professional finish as packaging printers need it to cut everything perfectly for you.

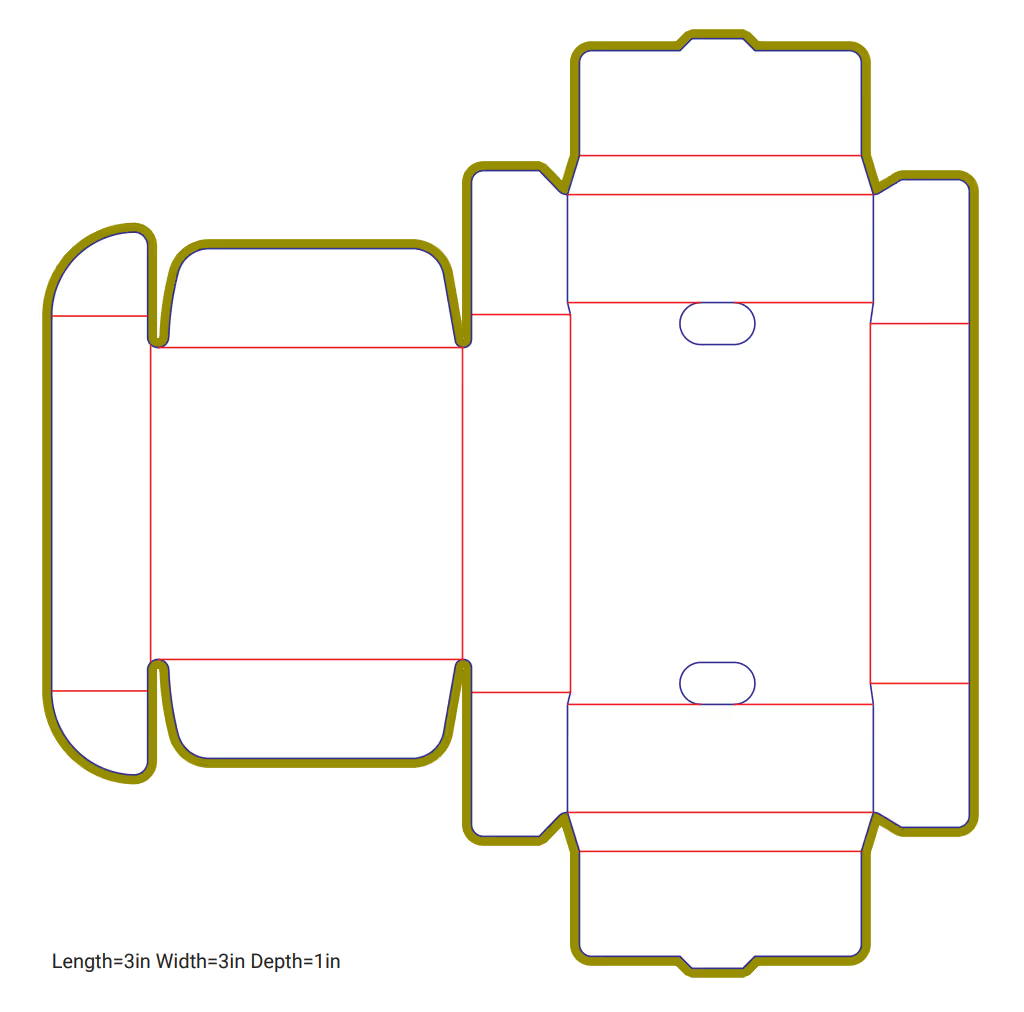

Die-Cutting

Die-cutting is the process of creating custom shapes for packaging materials. It's comparable to using cookie cutters to shape cookies into different shapes like stars or trees. It's a fantastic way of making your packaging stand out from competitors.

This process is often more expensive than standard sizes but also makes your packaging look extra special.

Embossing or Debossing

Embossing and debossing are incredible ways to make packaging like boxes or labels look different.

- Embossing pops up parts of the design. It makes them stand out and feel lovely to touch. This is a great way of showing off logos or patterns.

- Debossing is the opposite. It presses parts of the design down to create a cool, indented look. This will add a subtle touch of class and texture.

Both methods can be mixed with other techniques, like shiny foil stamping, to make packaging that really catches the eye and feels awesome.

Foil Stamping

Foil stamping is an incredible way to make your packaging look fancy by adding shiny, metallic design elements. It works by pressing a thin foil onto the packaging with heat and pressure using a unique mold.

You can choose from shiny metals like gold or silver to make logos or text really stand out. It makes packaging designs look and feel premium. It adds a bit of luxury and can be mixed with other techniques to make your packaging eye-catching.

Finishing Options

Design by Mardoodles Company

Printing companies will allow you to add a finish to your packaging. This section breaks down what each of your options means.

Spot UV Coating

Spot UV coating is a printing technique that adds a shiny, glossy layer to certain parts of your packaging like the logo to make those areas pop out from the background. The printing company applies a special, shiny varnish to the selected spots and then dries them quickly with UV light.

This method really brings out the details, adding a luxurious feel that makes the packaging look more appealing and high-quality.

Matte and Gloss

Matte and gloss are both finishing options. The printing company applies a layer of coating that gives your packaging a distinct look and adds another layer of protection.

- Matte — This finish gives your packaging a soft, non-reflective look that cuts down on glare and hides fingerprints. It works great on materials like paperboard and plastic.

- Gloss — This finish makes your packaging shiny and bright. It makes colors pop and grabs attention. Try it on custom labels to make your product packaging stand out on store shelves.

Both have their unique appeal depending on what you're going for. You can order samples to see which finish looks better for you.

Uncoated

If you don't want to add a finish, you can leave your packaging materials uncoated.

Uncoated packaging materials give off a friendlier, down-to-earth vibe. They're great for marketing materials like business cards.

They resonate with eco-friendly shoppers. They're amazing for campaigns that need a touch of authenticity.

Window Cutouts

Window cutouts are custom openings in boxes and other types of packaging that let you see their content without opening them. They're designed to protect the item and make it look appealing on the shelf.

It is possible to have window cutouts in different shapes and sizes to make the packaging look even more extraordinary.

Eco-Friendly Packaging

Eco-Friendly Boxes by Here and There Weddings

All signs point to eco-friendly packaging being the future of the industry. But what does that mean exactly? Let's define some of the terms associated with eco-friendly packaging.

Biodegradable vs Compostable

Biodegradable and compostable are terms that refer to things that can break down and return to nature. These are great features to have in your product packaging.

While these words are often used interchangeably, there's a slight difference between the two:

- Biodegradable — Something can be broken down by tiny organisms like bacteria. However, biodegradable things can take a while to break down, especially in places without much oxygen. They might even release a greenhouse gas called methane.

- Compostable — Things that can turn into compost under the right conditions. This usually means being in a particular place with enough heat, moisture, and air that helps it break down fast and leave nothing terrible behind.

So, while both types eventually return to nature, compostable products aim to do so more efficiently and eco-friendly by turning into something that enriches the soil.

When picking out eco-friendly packaging, it's good to think about how it's supposed to be disposed of to ensure customers can genuinely do their part in saving the planet.

Recyclable

Recyclable packaging includes paper and cardboard packaging. These are materials that customers can send in for collecting, sorting, cleaning, and processing so they can be repurposed into new products.

Using recyclable packaging helps cut down waste and saves natural resources.

Industry-Specific

Here are some industry-specific packaging terms you'll likely encounter along with their definitions.

Point-of-Purchase Displays (Shelf-Ready Displays)

Point-of-purchase displays (sometimes referred to as shelf-ready displays) are packaging and marketing materials placed near checkout areas or busy spots in stores. They aim to grab customers' attention and encourage them to buy products on the spot.

These displays use bright graphics to attract shoppers. They help increase sales and improve the shopping experience by making products more visible.

E-commerce

E-commerce means buying and selling goods and services online. It uses the internet to make transactions without needing physical stores. This includes online shopping, digital downloads, online auctions, or any other business transaction done over the internet.

Packaging Labels

Here are terminologies you'd encounter when ordering custom labels for your product and shipping boxes.

UPC, EAN, SKU

UPC, EAN, and SKU are codes that help stores keep track of their inventory.

- UPC (Universal Product Code) is a 12-digit code you see on products mainly in North America. It helps cashiers quickly determine the price and details of a product being bought.

- EAN does pretty much the same thing as UPC. The difference is that it has 13 digits and is used on products worldwide, not just in North America.

- SKU (Stock Keeping Unit) is a bit different. It's a unique code that each store or business makes up to keep an eye on their stock. It can tell them a lot like a product's size or color. However, it's not universal like UPC and EAN.

FDA Compliance

FDA compliance means following the rules set by the US Food and Drug Administration (FDA) to ensure that food, drugs, medical devices, cosmetics, and other products are safe and effective.

Companies making or selling these products must:

- Meet specific safety, quality, and performance standards

- Keep accurate records

- Carry out inspections

- Report any problems

The rules vary by product type — like different ones for food versus drugs. Keeping up with these regulations and having a good quality management system are crucial to staying compliant.

Not following these rules can lead to warnings, product recalls, fines, or other penalties, affecting both the company and public trust in these products.

Different Functions of Packaging Labels

Packaging labels are important for several reasons. They help shoppers recognize what they're buying by listing things like the product name, brand, and what it's made of.

Labels also tell you how to use the product safely, when it will go bad, and if it meets certain criteria like being organic or allergy-friendly.

Plus, they're a way for companies to share their message and values through text or design. Labels can even show if a product is eco-friendly, helping customers make choices that are better for the planet.

In short, labels on packaging give us the info we need to make smart choices when shopping.

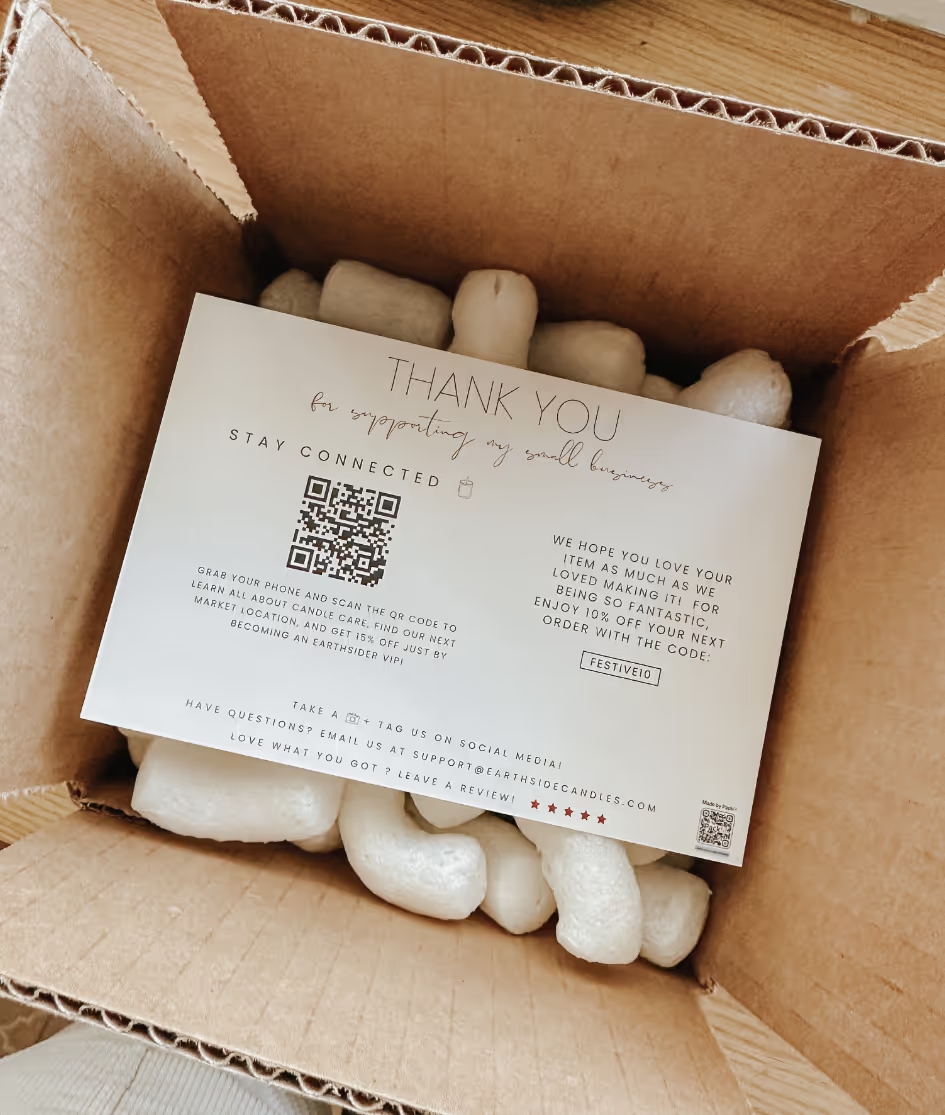

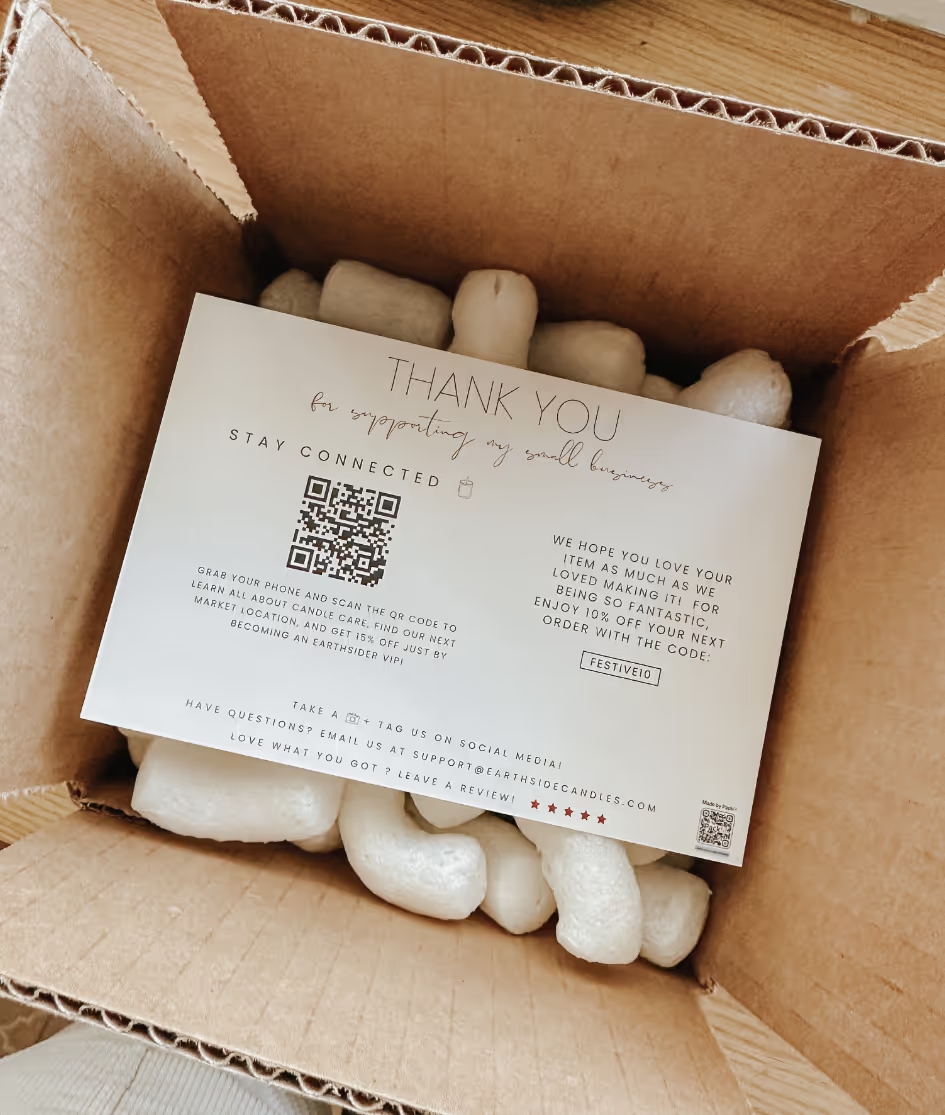

Importance of Packaging in the Customer Journey

Packaging Design by Earthside Co

Packaging serves as a product's first impression — it's what consumers see first. It conveys a lot about what lies beneath the surface.

Imagine you're strolling through a store's aisles. The items with the most appealing packaging will catch your eye, correct? That's because packaging is crucial in attracting attention and sparking curiosity.

Effective packaging isn't all about aesthetics. It also communicates essential information about the product, such as its purpose and why you should buy it.

Once you've picked up an item, the quality of its packaging can significantly influence your purchasing decision. A product encased in sturdy, premium-looking packaging can reassure you about the purchase, whereas one in cheap or uninviting packaging may cause you to reconsider.

And the importance of packaging doesn't end after the sale. Bringing a product home only to discover that its packaging is inadequate or fails to protect it will disappoint buyers.

Conversely, packaging that performs its role effectively—not only safeguarding the item but also maintaining its aesthetic appeal—enhances a customer's overall satisfaction and promotes loyalty to the brand.

So packaging isn't merely superficial. It plays an essential role throughout the entire consumer experience, from initial attraction to post-purchase satisfaction.